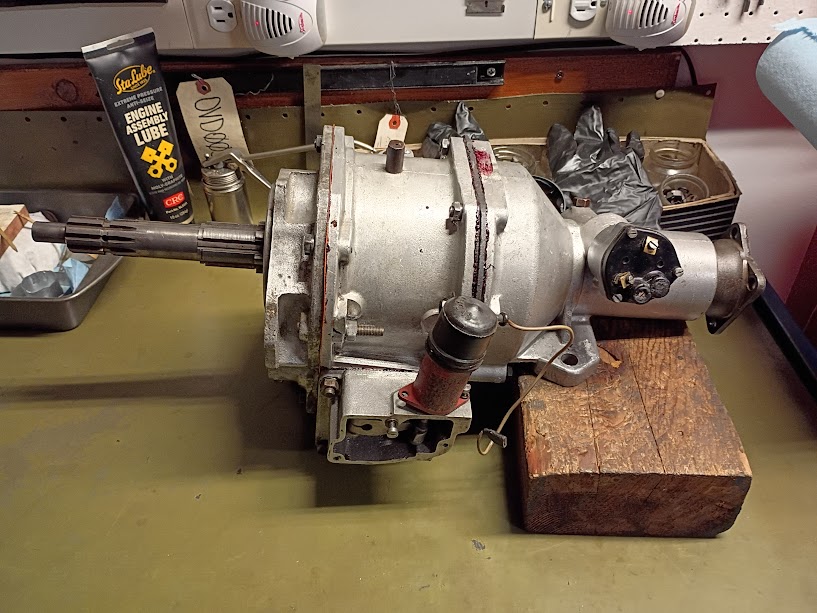

Typically, when I recondition an overdrive I start with a complete, whole unit then disassemble and clean, add new bearings and parts and reassemble as per the textbook. In this case, I acquired most of the unit but some key parts we missing. That’s not as desirable as the factory, when ther was one, strived for producing units with matched parts.

So, upon gathering all the necessary missing items, I attempted to reassemble the unit. Not everything was sliding together. The epicyclic nature of the overdrive, requires that parts cleanly work on center-smoothly. There should be no resistance when sliding it together.

Due to the various mismatched parts the mainshaft was not going all the way home into the pilot bushing, hanging up just short of the home position. Disassembled and assembled it 4 times! Changed the roller clutch with some other examples. Dremeled the teeth to eliminate any burrs.

Finally after fitting and refitting positions by rotating the mechanism, the unit buttoned up successfully. Moral of this story-start with a whole overdrive and don’t use substitute parts.