Its been 7 months since we had a tech session (which covered Laycock De Normanville overdrives). Then we had word of a pandemic, then fires, smoke, political unrest…such is 2020. So now, the completion of the tech session.

It took all this time to locate missing or perished parts, and replace wrongly used UNF hardware with BSF items that were buggered or crossthreaded. With the help of my friend Kent Lambert, in Hood River and British Tool Supply in New York, the unit is finally back together with its matching 3-speed transmission (remember the rust bucket it was), rolling smoothly, and all nuts and bolts intact and not leaking any oil. A covid miracle?

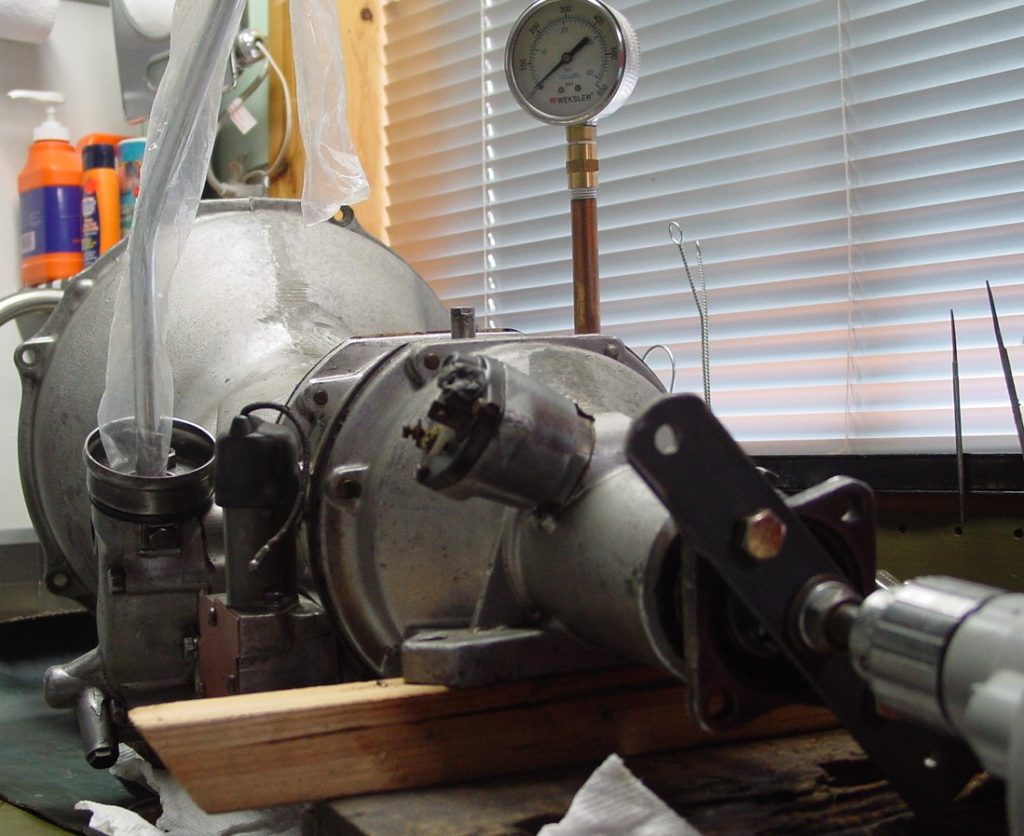

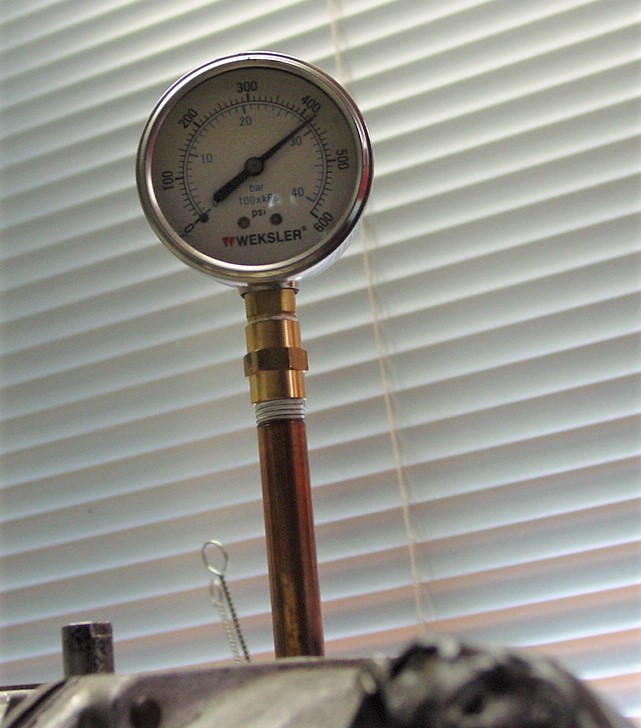

It is now time for the test. In order for the overdrive to function, it must overcome the pressure of the 8 springs which keep the clutch in direct drive position. (remember the coil bound weary springs, wrongly placed? -Kent had replacements). This is accomplished with hydraulic pressure using the 30W transmission oil compressed thru the overdrive accumulator and pump. Pressure must develop between 400-500 PSI to do this shift into overdrive. Using an adapter at the rear u-joint connection, and an electric drill running in reverse, and a special gauge attached to the overdrive valve, one can observe if the unit is functioning correctly. Results show-it is!!

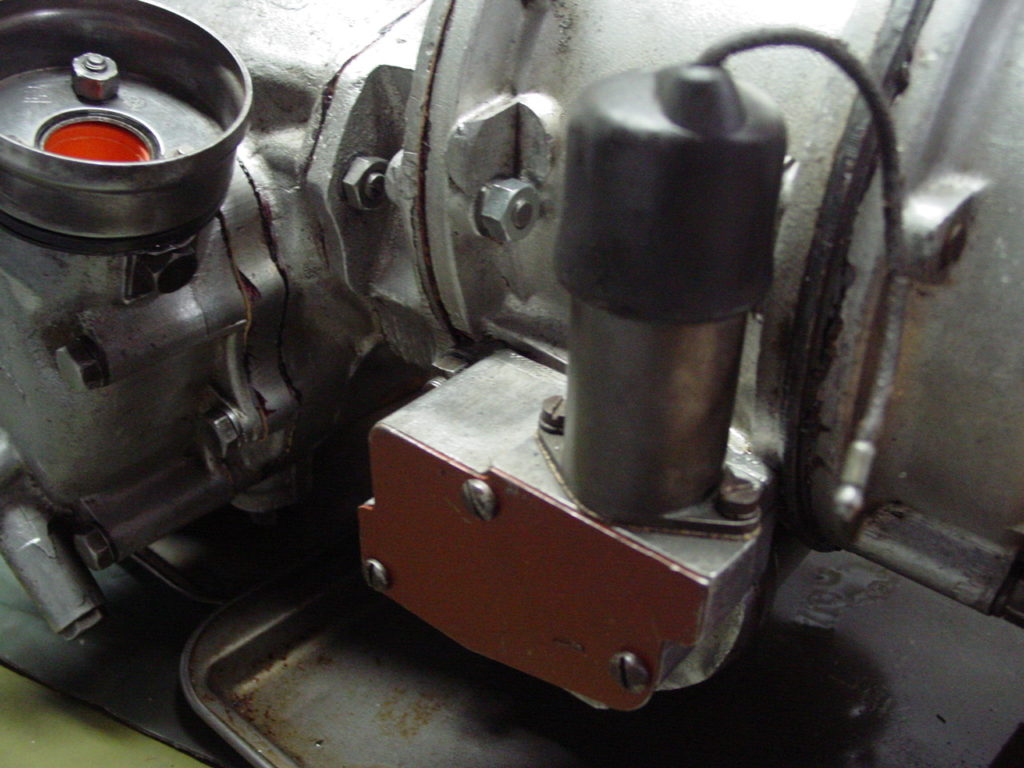

So now, when the operator is ready to use overdrive, he flips the toggle switch on the dash, that energizes the solenoid on the overdrive to open the valve and allow the 400+ pounds of pressure to move the clutch disc from its rearward direct drive position; to its forward overdrive position; engaging the epicyclic sun gear on the outer rim of the annulus; and overdrive is achieved! All done with the simple flip of a switch…a modern miracle. Now if we could just develop a vaccine…